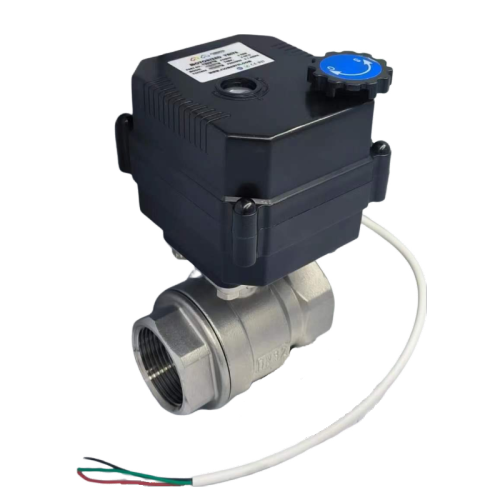

OP03 Wiring - 3 Wires, 3/4 1 1/2 motorized ball valves 1 inch

- Model

- FH-MO-4

Item specifics

- Actuator color

- Black ( customizable)

- Valve material

- PVC, Brass, SS304 for option

- Valve size

- 1/4''-1'' (DN8-DN25)

- Thread

- BSP, NPT for option

Review

Description

Motor ball valve ball valve

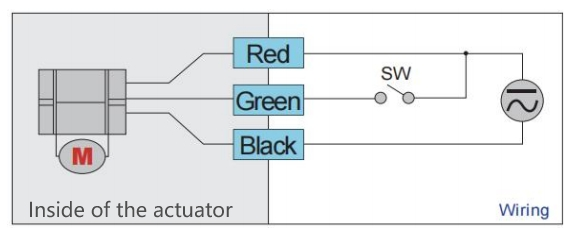

OP03, 3 wiring 1 point control

1. Connects Red Wire And Green Wire To Positive Pole, Black Wire To Negative Pole, The Ball Valve Opens.

2. Disconnects Green Wire, The Ball Valve Closes.

※ Once In Position, There Will Be No Power Consumption.

※ In Case Of Power Loss, Valve Will Remain In Its Current State.

※ Voltage Of Power Supply For Option:5V DC/9-24V ADC/220V AC

※ A On/Off Switch Can Be Installed In Line With Green Wire For A Simple Set Up.

This OP03 Electric Ball Actuator Uses A Constant Power And Ground Wire While A Third Green Wire Is Used For The Control Switch To Open And Close The Valve.

Click To Check Other Wirings Available.

Features

∎ Precision metal gear, high strength, reliable performance, long service life

∎ Multiple wiring for remote control and valve status feedback to intelligent control unit

∎ Floating sealing ball valve, no leakage

∎ Low power consumption, battery workable

∎ Flame retarded PC-ABS enclosure with compact, exquisite structure for small equipment

∎ IP 67 protection, applicable for humid environment

∎ With visual position indicator

∎ Various connectors customizable

∎ Manual override available for option

Application

Electric motor ball valve - widely used in water treatment systems, home automation, HVAC system, irrigation system, wildfire emergency sprinkler system, recreational vehicle (RV), trailer home, sprinkler truck, fire truck, air compressor etc., where automatic remote fluid control is needed.

How electric motor ball valve works?

Electric motor ball valves are designed with an electric motor actuator that rotates the ball inside the valve body, allowing or blocking the flow of fluids. This design ensures quick response times and precise control, making them ideal for applications requiring frequent adjustments or precise flow rates.

The key component of an electric motor ball valve is the motor actuator. This motor actuator is connected to the valve body and controls the position of the ball inside. When the motor actuator receives a signal, it rotates the ball to either open or close the valve. The actuator can be operated manually or remotely, depending on the application and requirements.

The ball inside the valve body has a hole or port through which the fluid flows. When the valve is open, the ball aligns with the flow path, allowing the fluid to pass through. Conversely, when the valve is closed, the ball rotates to block the flow path, preventing the fluid from passing through.

The design of the ball and the sealing mechanism ensures a tight and leak-free seal when the valve is in the closed position. This is essential in applications where the prevention of fluid leakage is crucial, such as in oil and gas pipelines or chemical processing plants.

Electric motor ball valves are available in various sizes and materials to suit different applications. They can be made from materials such as stainless steel, brass, or PVC, depending on the media being controlled and the environmental conditions.

In summary, electric motor ball valves work by using an electric motor actuator to rotate a ball inside the valve body, controlling the flow of fluids. Their design allows for quick response times and precise control, making them ideal for applications requiring accurate flow control.

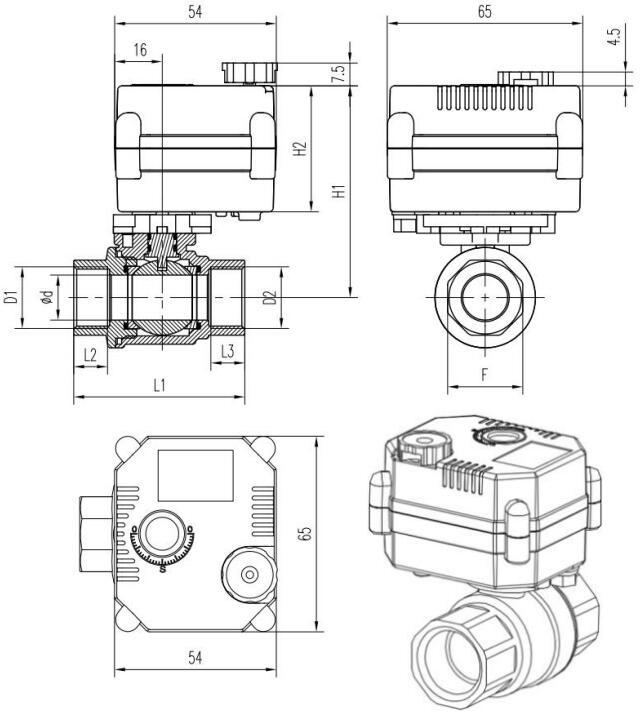

Dimension

D1/D2 | DN | φd | L1 | L2/L3 |

F

|

H1

|

H2

|

Weight (KG)

|

1/4'' | DN8 | 8 | 45 | 10 |

21

|

68

|

42

|

0.25

|

1/2'' | DN15 | 15 | 57 | 11 | 25 | 71 | 42 | 0.31 |

3/4'' | DN20 | 20 | 63 | 12 |

31

|

74

|

42

|

0.40

|

1'' | DN25 | 25 | 73 | 16 |

37

|

77

|

42

|

0.51

|

Unit: mm

Technical parameters

Series | Torque | Operating time | Working voltage |

Working current

|

Max. power

|

Max. pressure

|

FH | 2.5 N.M | <5S | 3-6V DC, 9-24V ADC, 110-230V AC |

<100 mA

|

5W

|

1.0 Mpa

|

Medium temperature | Ambient temperature | Humidity | Enclosure |

Service life

|

Wiring |

|

0-100℃/32-212℉ | -20-45℃/-4 -113℉ | 95% | IP67 |

50,000 - 80,000 times

|

OP01, OP02, OP03, OP04, OP05 optional, customization available |

Certifications

Factory

Manufacturer sepcialized in electric motor ball valve.