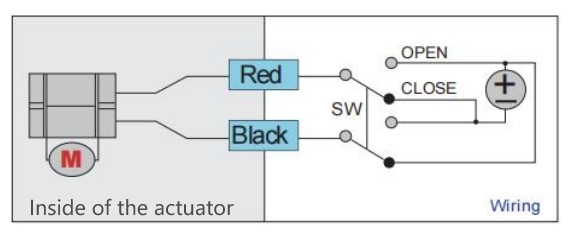

OP01 Wiring - 2 Wires, Reverse Polarity control electric motor actuator ball valve

- Model

- FH-MO-4

Item specifics

- Actuator color

- Black ( customizable)

- Valve material

- PVC, Brass, SS304 for option

- Valve size

- 1/4''-1'' (DN8-DN25)

- Thread

- BSP, NPT for option

- Wiring control

- 2 wires, 3 wires, 5 wires for option

- Manual override

- Optional

- Position indicator

- Yes

Review

Description

1. Connects Red Wire To Positive Pole, Black Wire To Negative Pole, The Electric Ball Valve Opens.

2. Reverse Polarity, The Eletric Ball Valve Closes.

※ Once In Position, There Will Be No Power Consumption.

※ In Case Of Power Loss, Valve Will Remain In Its Current State.

※ Voltage Of Power Supply For Option:5V DC/12V DC/9-35V DC

※ A DPDT Switch Is Suggested For A Simple Set Up.

Click to check other wirings available.

∎ Precision metal gear, high strength, reliable performance, long service life

∎ Multiple wiring for remote control and valve status feedback to intelligent control unit

∎ Floating sealing ball valve, no leakage

∎ Low power consumption, battery workable

∎ Flame retarded PC-ABS enclosure with compact, exquisite structure for small equipment

∎ IP 67 protection, applicable for humid environment

∎ With visual position indicator

∎ Various connectors customizable

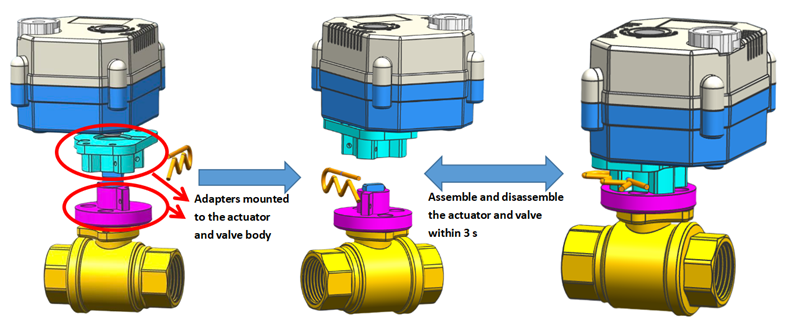

∎ Manual override available for option

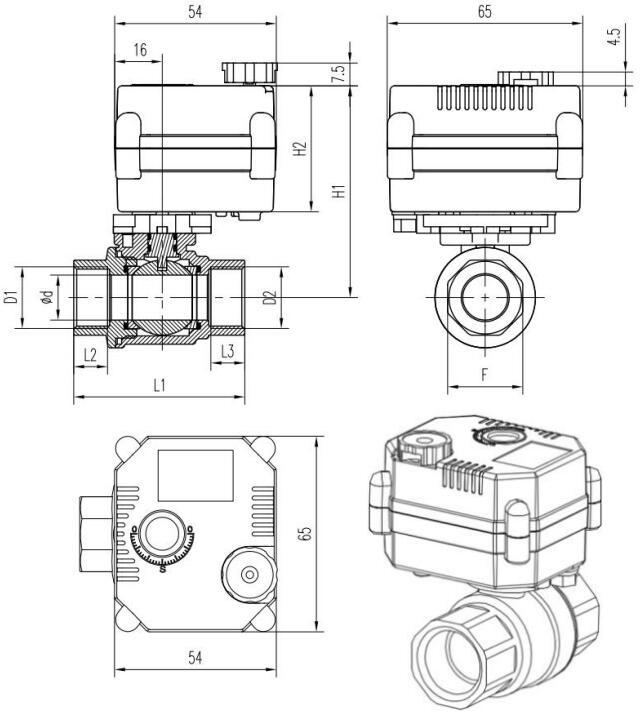

D1/D2 | DN | φd | L1 | L2/L3 |

F

|

H1

|

H2

|

Weight (KG)

|

1/4'' | DN8 | 8 | 45 | 10 |

21

|

68

|

42

|

0.25

|

1/2'' | DN15 | 15 | 57 | 11 | 25 | 71 | 42 | 0.31 |

3/4'' | DN20 | 20 | 63 | 12 |

31

|

74

|

42

|

0.40

|

1'' | DN25 | 25 | 73 | 16 |

37

|

77

|

42

|

0.51

|

Series | Torque | Operating time | Working voltage |

Working current

|

Max. power

|

Max. pressure

|

FH | 2.5 N.M | <5S | 3-6V DC, 9-24V ADC, 110-230V AC |

<100 mA

|

5W

|

1.0 Mpa

|

Medium temperature | Ambient temperature | Humidity | Enclosure |

Service life

|

Wiring |

|

0-100℃/32-212℉ | -20-45℃/-4 -113℉ | 95% | IP67 |

50,000 - 80,000 times

|

OP01, OP02, OP03, OP04, OP05 optional, customization available |