OP05-5 wires, with valve position output, mini motorized ball valve

- Model

- FH-MO-11

Item specifics

- Actuator color

- Black (customizable for bulk order)

- Valve material

- PVC, Brass, SS304 for option

- Valve size

- 1/4''-1'' (DN8-DN25)

- Thread

- BSP, NPT for option

- Wiring

- 2 wires, 3 wires, 5 wires etc.

- Voltage

- 5VDC, 9-24VADC, 110-220VADC

- Manual override

- Optional

- Position indicator

- Yes

- OPEN/close time

- 3s

- Coil connection

- 35cm (13'') Lead Wires

- Output torque

- 2.5NM

- Standard pressure

- 1.0 Mpa

Review

Description

Mini motorized ball valve

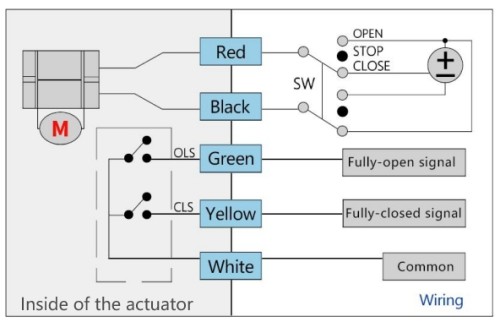

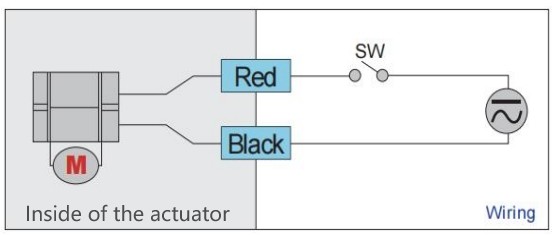

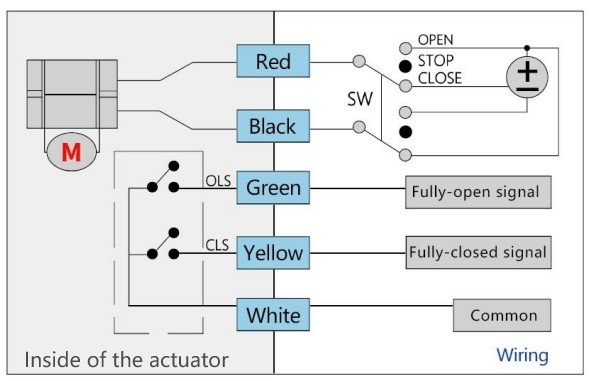

OP05 Wiring - 5 Wires,With Valve Position Feedback

1. There Should Be 2 Power Supply, One For Electric Ball Valve Actuator - Red Wire To Positive Pole, Black Wire To Negative Pole; Another One For Customer’S Position Indication Devices - The Green Wire Outputting Fully-Open Signal Connects To Open Position Indication Device, The Yellow Wire Outputting Fully-Closed Signal Connects To the Close Position Indication Device, And The Devices Both Should Be Connected To The Positive Pole Of The Power Supply, And The White Wire Of The Electric Ball Valve Actuator Connects To Negative Pole Of The Power Supply, There Conforms A Closed Circuit. The Valve Opens, The Open Position Indication Device Receives The Fully-Open Signal, Will Light Up If Lights Are Used As Position Indication Devices.

2. Reverse Polarity of the ball valve wiring, The Ball Valve Closes, The Close Position Indication Device Receives The Fully-Closed Signal, Will Light Up If Lights Are Used As Position Indication Devices.

※ Once In Position, There Will Be No Power Consumption For Electric Ball Valve, Nomial Power Consumption For Position Indication Devices.

※ In Case Of Power Loss, Valve Will Remain In Its Current State.

※ Voltage Of Power Supply For Option:5V DC/12V DC/24V DC

※ A DPDT Switch Is Suggested For A Simple Set Up.

Features

∎ Precision metal gear, high strength, reliable performance, long service life

∎ Multiple wiring for remote control and valve status feedback to intelligent control unit

∎ Floating sealing ball valve, no leakage

∎ Low power consumption, battery workable

∎ Flame retarded PC-ABS enclosure with compact, exquisite structure for small equipment

∎ IP 67 protection, applicable for humid environment

∎ With visual position indicator

∎ Various connectors customizable

∎ Manual override available for option

Application

Mini motorized ball valves - widely used in water treatment systems, home automation, HVAC system, irrigation system, wildfire emergency sprinkler system, recreational vehicle (RV), trailer home, sprinkler truck, fire truck, air compressor, washing machine, etc.

Advantages of mini motorized ball valve

Mini motorized ball valves offer numerous advantages over traditional manual valves.

Firstly, with a well-set compact design, it has the smallest size comapred to similar products in the market, which makes them easy to install in tight spaces. This is particularly beneficial in applications where space is limited, such as in small machine and equipments, in HVAC systems or compact industrial setups. Additionally, mini motorized ball valves consume energy only during the actual opening and closing process, and only negligible amounts once fully opened, consuming very little power makes them energy-efficient and cost-effective in the long run. And on the other side it also means it can be permanently connected without risk of overheating or burning out, which makes it a better choice when the valve needs to remain in position for an extended period of time.

Another advantage of mini motorized ball valves is their quick response time. With the ability to open or close in a matter of seconds, these valves enable rapid adjustments to changing process conditions. This is crucial in applications where precise control is required to maintain optimal performance.

Furthermore, mini motorized ball valves are highly reliable and require minimal maintenance. Unlike manual valves that may become stiff or prone to leaks over time, mini electric ball valves offer consistent performance and reduced downtime. Their automated functionality also reduces the risk of human error, ensuring accurate and repeatable operations.

The OP05 5 wires set up with valve position feedback wires enable to send back valve status to control hub for remote in-time ball valve position monitor.

Dimension

D1/D2 | DN | φd | L1 | L2/L3 |

F

|

H1

|

H2

|

Weight (KG)

|

1/4'' | DN8 | 8 | 45 | 10 |

21

|

68

|

42

|

0.25

|

1/2'' | DN15 | 15 | 57 | 11 | 25 | 71 | 42 | 0.31 |

3/4'' | DN20 | 20 | 63 | 12 |

31

|

74

|

42

|

0.40

|

1'' | DN25 | 25 | 73 | 16 |

37

|

77

|

42

|

0.51

|

Unit: mm

Technical parameters

Series | Torque | Operating time | Working voltage |

Working current

|

Max. power

|

Max. pressure

|

FH | 2.5 N.M | <5S | 3-6V DC, 9-24V ADC, 110-230V AC |

<100 mA

|

5W

|

1.0 Mpa

|

Medium temperature | Ambient temperature | Humidity | Enclosure |

Service life

|

Wiring |

|

0-100℃/32-212℉ | -20-45℃/-4 -113℉ | 95% | IP67 |

50,000 - 80,000 times

|

OP01, OP02, OP03, OP04, OP05 optional, customization available |

Certifications

Factory

Manufacturer sepcialized in mini electric ball valve.